We got it.

Thank you for contacting us.We’ll get back to you as soon as possible.

How Machining Shops Can Attract OEM Buyers

By Doug Mansfield • December 30, 2025

The Tire-Kicker Problem

After over 400 SBA consultations and serving over 300 clients, including many precision machining companies, I have heard the same frustration: "We get plenty of inquiries, but they're all tire-kickers asking for quotes on one-off prototype parts."

Real customers are aerospace OEMs, medical device manufacturers, and automotive Tier 1 suppliers who need recurring production runs. Your website attracts hobbyists building custom motorcycles and inventors wanting single parts for Kickstarter projects because it's designed to attract everyone.

Machining company websites often operate as digital brochures listing capabilities rather than qualification funnels filtering for ideal customers.

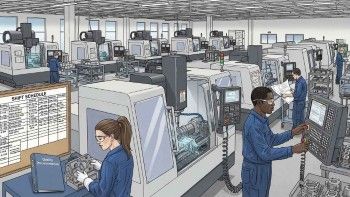

Capability Lists Tell Engineers Nothing

Walk through ten precision machining websites. You'll see similar content patterns:

"5-axis CNC machining, Swiss turning, EDM, inspection equipment, ISO 9001 certified, experienced team."

That tells a hobbyist "Yes, we can make your part." It tells an aerospace procurement manager nothing about whether you understand their requirements for titanium turbine components with tight tolerances and AS9100D documentation.

Equipment lists say "We have machines." They don't say "We've solved problems like yours."

I see this in consultations. A shop specializes in medical device manufacturing but their homepage says "We serve all industries." Another has deep aerospace experience but buries it under generic "quality machining services" messaging.

When you position as a generalist, you attract inquiries from anyone who needs anything machined. Many of those inquiries are terrible fits.

How OEM Buyers Actually Research

Engineers researching suppliers for production programs don't Google "CNC machining services." They start with specific requirements and work backward.

Aerospace buyers check for AS9100D certification, evidence of titanium experience, case studies showing documented tolerances achieved, and inspection capabilities. Medical device procurement looks for ISO 13485, FDA documentation experience, and biocompatibility material handling. Automotive Tier 1 focuses on IATF 16949, PPAP documentation, and volume capacity.

At no point does an equipment list matter. They assume you have 5-axis capability if you're quoting aerospace work. What they're evaluating is proof you've successfully handled their specific type of work before.

Case Studies That Prove Competence

Many machining companies have no case studies, or generic ones that could apply to any shop.

"We machined a complex part for a satisfied customer. On time, within spec, great quality."

That tells an engineer nothing. Compare that to:

"Titanium Ti-6Al-4V turbine housing for aerospace application. 47 features including internal cooling passages. Tolerance requirements: plus or minus 0.0002 inches on critical dimensions. 5-axis simultaneous machining required. Material traceability and AS9100D documentation provided. First article inspection passed without revision."

Now you've proven competence.

Many shops resist this specificity because they worry it narrows their appeal. Opposite is true. Deep expertise in one demanding application proves capability for others. An aerospace buyer seeing detailed medical device case studies thinks "If they can handle FDA requirements, they can handle our work."

What doesn't work: showing hobbyist project case studies alongside aerospace work. That signals you're not serious about production contracts.

Filter Before the Inquiry

You want to make it harder for unqualified prospects to contact you while making it easier for qualified prospects to engage.

Generic contact forms generate maximum inquiries from minimum qualified prospects. "Name, email, tell us about your project" gets filled out by everyone.

Better approach: qualification-based inquiry forms. Ask about industry, production volume, tolerance requirements, and certifications needed. A hobbyist wanting one aluminum part sees this form and realizes you're not set up for their work. They go elsewhere.

That's exactly what you want.

When qualified inquiries come through, sales already knows it's an aerospace customer needing recurring titanium production with tight tolerances. Discovery focuses on technical requirements instead of basic qualification.

Certifications Need Context

Certifications matter enormously. Many websites communicate them wrong.

Wrong: logos at the bottom of the homepage with no context.

Right: dedicated quality page explaining what each certification means, scope of certification, and what it proves about your capabilities.

AS9100D isn't just a logo. If you hold it, explain what that means: "Our AS9100D certification requires full traceability from raw material through final inspection, with documented process controls and statistical verification of critical features."

Engineers care about the systems behind the certifications, not the logos.

The Volume vs. Qualification Tradeoff

Lead generation for precision machining isn't about getting more inquiries. It's about getting the right inquiries from prospects who become long-term production customers.

Fewer total inquiries, higher percentage qualified, better conversion to actual contracts.

Requires confidence. You'll turn away hobbyist work. You'll tell price shoppers you're not the right fit. You'll focus on customers who value expertise over lowest price.

One aerospace production program is worth more than dozens of one-off quotes that never convert.

Contact Mansfield Marketing to discuss restructuring your lead generation from volume-focused to qualification-focused.

Frequently Asked Questions

What if we legitimately do both prototype and production work?

Separate the messaging. Create distinct pages or sections for rapid prototyping versus production machining, each speaking to different buyer needs. An aerospace OEM evaluating you for production contracts shouldn't land on content designed for inventors needing one-off parts. Let each audience find content that speaks directly to them.

Won't qualification forms scare away good prospects too?

Qualified buyers expect qualification questions. An aerospace procurement manager understands why you're asking about volume requirements and certifications. They ask vendors similar questions. The prospects scared off by a few targeted questions weren't going to survive your actual quoting process anyway.

How detailed should case studies be if we have NDAs with customers?

Focus on technical details rather than customer names. You can describe tolerances achieved, materials machined, inspection methods used, and documentation provided without identifying who the part was for. "Titanium aerospace component with ±.0002" on critical features" proves competence regardless of whether you name the operator.

Written by Doug Mansfield | President, Mansfield Marketing

Connect with Doug Mansfield on LinkedIn