We got it.

Thank you for contacting us.We’ll get back to you as soon as possible.

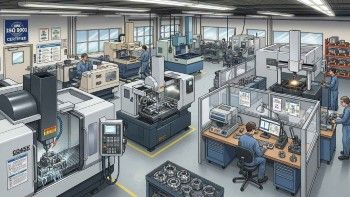

How Job Shops Qualify for Aerospace Production Searches

By Doug Mansfield • February 5, 2026

Understanding Aerospace Buyer Qualification Requirements

I've observed precision machining shops sometimes demonstrating a disconnect with how aerospace procurement teams evaluate suppliers. Machining companies display capabilities prominently while aerospace buyers search for certifications first. The qualification sequence determines whether your shop enters consideration before capabilities even matter.

Aerospace procurement operates through strict verification protocols. Before reviewing your equipment list or requesting quotes, buyers verify AS9100 certification, ITAR registration status, and approved process documentation. What I see on job shop websites is the reverse sequence, equipment counts and capability statements appearing before the certifications procurement teams use to qualify suppliers.

The positioning problem is simple. Generic "precision machining" messaging attracts prototype inquiries from commercial buyers with minimal qualification requirements. Aerospace-specific positioning communicating "AS9100 aerospace manufacturing" targets procurement managers following defense contractor qualification protocols. I've learned the difference between these search patterns determines whether shops receive prototype RFQ requests or production contract opportunities.

What Aerospace Procurement Teams Verify Before Requesting Quotes

Aerospace buyers follow standardized verification workflows regardless of part complexity or contract value. The sequence starts with certification confirmation, moves to process approval validation, then concludes with capacity assessment. What makes this predictable is how procurement software and vendor management systems structure qualification checklists.

I notice job shops positioning certifications as credibility signals rather than qualification requirements. AS9100 logos appear in website footers alongside generic quality statements. ITAR registration gets mentioned in capability paragraphs. Defense contractor registration numbers hide in company overview sections. This placement assumes buyers research capabilities first and verify qualifications later.

The actual sequence reverses this completely. Procurement teams filter supplier databases by certification status before reviewing individual company profiles. Search engine optimization for aerospace production contracts means understanding buyers search "AS9100 machine shop Houston" before they search "precision machining aerospace parts." Certification-first positioning matches how procurement systems filter and sort potential suppliers.

Essential Aerospace Qualification Signals

What separates aerospace-qualified shops from general machining companies isn't just AS9100 certification. I see specific operational capabilities that aerospace buyers verify during supplier qualification audits.

First article inspection processes need explicit documentation. Aerospace contracts require dimensional verification, material certification, and process validation before production authorization. Job shops that communicate FAI capability and experience accelerate qualification timelines because buyers know inspection protocols are established.

Source inspection accommodation signals production readiness. When aerospace buyers send quality representatives to verify processes or witness critical operations, shops need physical space, documentation systems, and staff trained for audit protocols. What I've learned is that mentioning "source inspection welcome" or "customer witness points available" communicates operational maturity procurement teams require.

Government contract experience demonstrates administrative capability. Aerospace production involves DFARS compliance, export control procedures, and payment term structures different from commercial machining. Shops that reference prior defense work or current CAGE code registration signal they understand contractual requirements beyond manufacturing capability.

Material traceability systems separate prototype shops from production suppliers. Aerospace buyers verify material certification tracking, heat lot documentation, and chain of custody records. I notice shops mention "full material traceability" generically while buyers need specifics: what software tracks certifications, how batch numbers link to certifications, whether digital or physical documentation accompanies shipments.

Demonstrating Credentials Effectively on Your Website

The positioning sequence matters more than credential count. What I observe is shops listing AS9100, IATF 16949, and ISO 9001 together as equivalent quality signals. To aerospace procurement teams, these certifications communicate different capabilities. AS9100 specifically addresses aerospace requirements. The other certifications demonstrate quality system maturity but don't qualify shops for aerospace work alone.

Homepage placement determines whether procurement teams continue researching your capabilities. I see certification badges relegated to footer positions or buried in "About Us" sections. Aerospace buyers scanning multiple potential suppliers need immediate qualification confirmation. Top-of-page certification display with registration numbers and scope statements answers their first question: "Does this shop meet basic aerospace supplier requirements?"

Approved process lists deserve specific callouts. Aerospace manufacturing involves special processes—heat treating, welding, non-destructive testing, chemical processing—requiring individual certifications beyond AS9100 scope. What aerospace buyers verify is whether your Nadcap approvals, QPL listings, or OEM process certifications match their engineering specifications. Content marketing that highlights specific process approvals targets procurement teams cross-referencing approved supplier databases.

Defense contractor registration appears in specific search contexts. CAGE code, SAM registration, and DPAS rating communicate your shop can receive government contracts. I've learned aerospace prime contractors searching for subcontractors verify these registrations before initiating contact. Website content stating "Active CAGE code" or "SAM registered" filters you into consideration for defense production work.

Positioning for Production Contracts Instead of Prototypes

The language difference between prototype and production positioning is subtle but determines inquiry quality. I notice machining companies using interchangeable terms, "precision manufacturing," "custom machining," "prototype to production", attempting to attract all possible inquiries. What this creates is message confusion that attracts the wrong buyer personas.

Prototype buyers search differently than production procurement teams. "CNC machining quote" attracts one-off requests and design iteration work. "AS9100 contract manufacturing" targets buyers allocating production volume. What I see is shops optimizing for the first search pattern while wanting the second inquiry type.

Production-focused positioning requires operational specificity:

- Minimum order quantities communicate volume capability

- Lead time ranges for production runs versus prototype turnaround

- Capacity statements showing shift structure and equipment count

- Quality system descriptions mentioning production part approval processes

- Contract manufacturing experience demonstrating ongoing program management

These details filter prototype buyers while accelerating qualification for production opportunities. What I've learned is that being explicit about production focus reduces low-value inquiries more effectively than trying to serve all customer types equally.

Documentation That Qualifies Your Shop Faster

Aerospace procurement teams operate with predefined supplier qualification checklists. Before requesting quotes, buyers verify documentation proving your shop meets baseline requirements. I observe machining companies treating quality manuals, process flows, and capability matrices as internal documents rather than buyer qualification tools.

What accelerates qualification is providing documentation buyers need without requiring direct requests. Quality manual summaries showing your AS9100 scope, excluded processes, and certification dates answer procurement questions before formal contact. Approved process listings stating Nadcap accreditations, welding procedure qualifications, and special process certifications let buyers cross-reference their engineering requirements against your documented capabilities.

First article inspection templates demonstrate process maturity. Aerospace buyers receiving FAI documentation with every new part number know your shop follows production part approval protocols. Providing sample FAI formats or process descriptions on your website signals established inspection procedures procurement teams verify during audits.

Source inspection procedures communicate audit readiness. Describing how customer quality representatives access your facility, witness critical operations, or verify documentation shows you accommodate oversight aerospace contracts require. I notice shops avoid mentioning inspection protocols assuming buyers know all suppliers handle audits. Making inspection accommodation explicit differentiates production-ready shops from prototype operations.

Structuring Aerospace Marketing for Production Buyers

What changes aerospace inquiry quality is matching website content sequence to procurement team verification workflows. I see machining shops leading with equipment lists and capability statements because that's how they think about their business. Aerospace buyers think about supplier qualification first, capability assessment second, capacity verification third.

The positioning sequence for aerospace production contracts starts with certifications to establish qualification. AS9100 registration, ITAR compliance, and defense contractor status appear prominently because these credentials determine whether procurement teams continue researching your shop. Without immediate qualification confirmation, buyers move to the next potential supplier.

After qualification comes capability demonstration. This is where approved process lists, material specifications, and tolerance ranges communicate technical scope. What I've learned is aerospace buyers need both regulatory qualification and technical capability confirmation before capacity assessment matters.

Capacity verification closes qualification. Equipment counts, shift structures, and facility square footage demonstrate production volume capability after regulatory and technical requirements are satisfied. Leading with capacity information before qualification confuses the procurement sequence buyers follow during supplier research.

Positioning Precision Machining for Aerospace Production

Aerospace procurement teams search for qualified suppliers using certification-specific terms. Generic precision machining positioning attracts prototype inquiries from commercial buyers. Aerospace-qualified positioning communicating regulatory compliance, process approvals, and defense contractor status targets production contracts with ongoing volume.

This requires restructuring website content to match aerospace buyer verification workflows. Certifications need prominence to establish qualification immediately. Process approvals require specific callouts matching approved supplier database searches. Documentation availability signals audit readiness procurement teams verify before awarding contracts.

What separates shops receiving aerospace production opportunities from those handling prototype work is how effectively website content answers procurement qualification questions. Buyers verify certifications first, capabilities second, capacity third. Websites organized around this sequence enter consideration faster and receive higher-value inquiries.

Mansfield Marketing works with precision machining shops to restructure website content for aerospace buyer qualification workflows and attract production contracts instead of prototype inquiries. Start by

requesting a quote or calling us at (713) 936-5557.

Written by Doug Mansfield | President, Mansfield Marketing

Connect with Doug Mansfield on LinkedIn