We got it.

Thank you for contacting us.We’ll get back to you as soon as possible.

What Procurement Teams Look for in Welding and Fabrication Partners

By Doug Mansfield • January 8, 2026

The Shortlist You Never Made

Procurement teams at refineries, chemical plants, and industrial facilities evaluate

welding and fabricationvendors through a systematic process. Most welding companies never see this process because they get eliminated before the first conversation happens.

The elimination occurs during desktop research. A procurement specialist pulls up your website, scans for specific information, doesn't find it, and moves to the next vendor on the list. Your phone never rings. You never know you were considered and rejected.

I've walked through this scenario in consultations with company owners who can't figure out why larger contracts go to competitors. The answer is sometimes: their website communicates to other welders, not to the people who actually approve vendor relationships.

Certifications Are Table Stakes

AWS certification matters. ASME code compliance matters. But listing "AWS Certified" on your homepage doesn't differentiate you from the dozens of other shops making the same claim.

Procurement wants specifics. Which certifications do your welders hold individually? D1.1 structural steel? D1.6 stainless? D17.1 aerospace? Are your procedures qualified for the materials and joint configurations the facility actually uses?

A refinery turnaround coordinator isn't impressed by generic certification claims. They need to know whether your crew can weld P91 chrome-moly pipe to their specific WPS requirements. If your website doesn't address this level of detail, you look like every other generalist in the market.

The welding companies that win procurement approval list individual welder qualifications, procedure qualification records on file, and the specific code work they're equipped to perform. This information should be findable within two clicks from your homepage.

Safety Records Decide Vendor Approval

EMR ratings matter more than most welding companies realize. An Experience Modification Rate above 1.0 can disqualify you from consideration at major facilities regardless of your technical capabilities.

Procurement teams at refineries and chemical plants face personal accountability for contractor safety performance. Bringing in a vendor with a poor safety record creates career risk. Given the choice between a technically excellent shop with a 1.3 EMR and a competent shop with a 0.8 EMR, procurement picks the safer bet every time.

Your website should display your current EMR prominently. If it's below 1.0, that's a competitive advantage worth highlighting. If you've maintained a low EMR for multiple consecutive years, say so. If you have zero recordable incidents over a meaningful timeframe, that belongs on your homepage.

Beyond EMR, procurement evaluates safety program documentation. Do you have a written safety manual? Drug testing protocols? JSA procedures for field work? ISNetworld or PICS compliance? These aren't optional extras for industrial work. They're prerequisites for getting on the approved vendor list.

Field Crew Availability Determines Project Fit

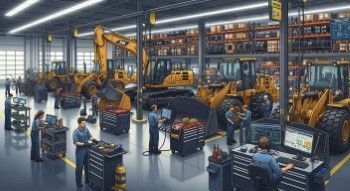

Shop fabrication capabilities matter, but field service capacity often determines whether you win the contract. Turnarounds, shutdowns, and emergency repairs require crews that can mobilize quickly and work on-site under facility supervision.

Procurement needs to understand your field deployment capabilities before they'll consider you for anything beyond shop work. How many certified welders can you put in the field simultaneously? What's your typical mobilization timeframe? Do you own the equipment for field work, or do you rent it project by project?

The welding companies that consistently win industrial contracts communicate field capabilities explicitly. They list mobile welding units, field crew size ranges, and geographic service areas. They show photos of actual field work at industrial sites, not stock images of someone welding in a clean shop environment.

Documentation Systems Signal Professionalism

Industrial clients require documentation that holds up to audit. Weld logs, material certifications, NDE reports, and as-built drawings all need to be traceable and retrievable. Procurement evaluates whether your systems can produce this documentation reliably.

A fabrication shop that delivers quality work but can't produce organized documentation creates problems for the facility's quality assurance team. Given the choice, procurement selects vendors who demonstrate documentation discipline upfront.

Your website should reference your quality management systems. Do you have ISO certification? A formal QA/QC program? Document control procedures? These details signal that you operate as a professional organization rather than a skilled trade working informally.

What Your Website Probably Gets Wrong

Most welding and fabrication websites focus on capabilities: MIG, TIG, stick, flux-core, plasma cutting, CNC machining. These lists describe what equipment you own. They don't answer the questions procurement actually asks.

Procurement wants to know whether you can be trusted with their facility, their timeline, and their audit requirements. Capability lists don't address trust. Proof points do.

- Specific certifications held by named personnel

- Current EMR and safety program details

- Field crew deployment capacity

- Quality system documentation

- References from comparable facilities

If a procurement specialist can't find this information on your website within sixty seconds, you've already lost the evaluation. They have a list of vendors to review. Yours just got crossed off.

The Proof Point Inventory

Take an honest look at your website through procurement's eyes. Can they find your EMR? Can they verify your AWS certifications are current? Can they see evidence of field work at industrial facilities similar to theirs?

If not, you're competing on the wrong criteria. You're hoping technical skill alone will win contracts that get decided on documentation, safety records, and demonstrated professionalism.

The welding companies that consistently win industrial work don't have better welders. They have better proof that they can be trusted with the contract.

Written by Doug Mansfield | President, Mansfield Marketing

Connect with Doug Mansfield on LinkedIn