We got it.

Thank you for contacting us.We’ll get back to you as soon as possible.

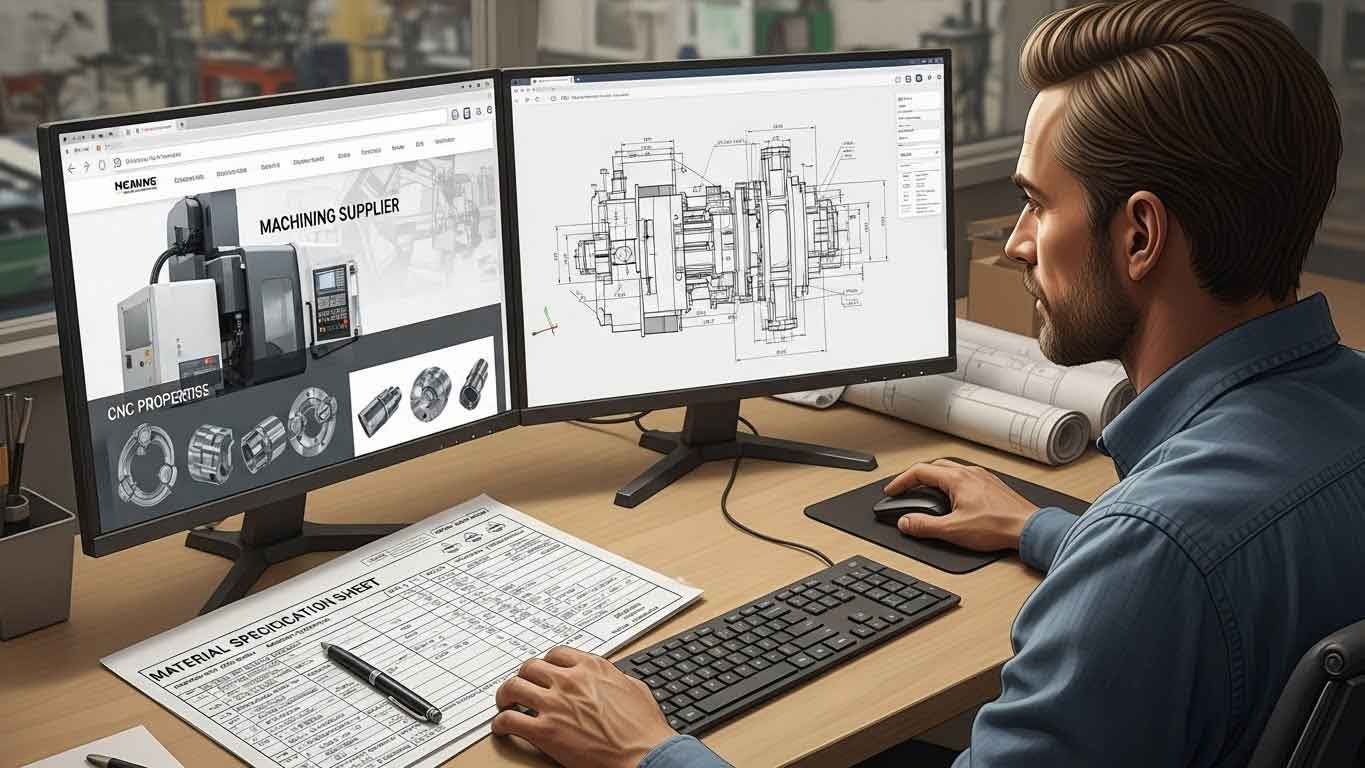

What Engineers Want to See on Precision Machining Websites

By Doug Mansfield • January 13, 2026

Two Audiences, One Website

Precision machining company websites serve two different audiences with completely different evaluation criteria. Purchasing agents care about pricing, lead times, and vendor qualification paperwork. Engineers care about whether the shop can actually make the part.

What I often see on machining websites is content built for the first audience. Services listed, quality commitments mentioned, contact form included. This works fine for transactional buyers shopping quotes.

But engineers aren't shopping quotes. They're determining technical fit before the RFQ ever gets issued. If a website doesn't pass engineering evaluation, purchasing never sees that shop's name on the approved supplier list.

Engineers Research Before Purchasing Gets Involved

The buying process at OEMs and contract manufacturers typically starts with an engineer who has a problem to solve. They need a supplier who can hold a specific tolerance on a specific material for a specific application. They research options, evaluate capabilities, and build a shortlist. Then they hand that shortlist to purchasing for quotes and vendor qualification.

This means machining websites need to convince an engineer before they ever need to convince a buyer. And engineers evaluate suppliers differently than purchasing agents do.

An engineer scanning a website isn't looking for company history or commitment to customer service. They're looking for evidence that the shop understands their technical requirements and has the capability to meet them.

Material Specifications Matter

Engineers work with specific materials for specific reasons. The aerospace engineer needs 6Al-4V titanium for weight and strength. The medical device engineer needs 316L stainless for biocompatibility. The semiconductor equipment engineer needs stress-relieved 6061-T6 for dimensional stability.

When a website says "we machine all materials," it tells the engineer nothing useful. They can't determine whether the shop has experience with their specific alloy, whether they understand its machining characteristics, or whether they can source it to the required specification.

The machining companies that win engineering approval get specific about materials. I see them list the alloys they work with regularly. They mention material certifications they can provide. They demonstrate understanding of the differences between machining 303 versus 304 versus 316 stainless, or the challenges of working with Inconel versus standard nickel alloys.

Material expertise signals technical depth. Generic capability claims signal a shop that takes whatever walks in the door.

Tolerance Data Needs Context

Every machining website claims tight tolerances. What I don't see is the context engineers need to evaluate those claims.

Holding ±.0005" on a simple OD turn in aluminum is routine work. Holding that same tolerance on a complex five-axis feature in titanium is genuinely difficult. When a website just says "we hold tight tolerances," the engineer has no way to assess actual capability level.

Context matters. What tolerances can the shop hold on what features in what materials? Do they have CMM inspection capability to verify critical dimensions? What's their process for handling parts where tolerance stack-up creates cumulative error risk?

I find that engineers respect specificity. A statement like "we routinely hold ±.001" on turned features and ±.002" on milled features in standard materials, with tighter tolerances available depending on geometry and material" gives an engineer something to evaluate. A generic "precision machining" claim gives them nothing.

Equipment Lists Without Context Are Useless

Equipment lists might include a Mazak 5-axis, a Haas VF-4, and a Star SR-20 Swiss lathe. To a machinist, that communicates something. To an engineer evaluating suppliers, it often communicates very little.

Engineers want to understand what equipment enables a shop to do, not just what they own. A 5-axis machine means they can handle complex geometries in single setups. A Swiss lathe means they can produce small-diameter turned parts efficiently. A large-envelope VMC means they can handle bigger workpieces.

What works better is connecting equipment to capability. Instead of just listing machine models, explain what problems each machine solves. What part sizes can the shop handle? What level of complexity? What production volumes make sense for the setup?

The goal isn't to impress engineers with expensive equipment. It's to help them quickly determine whether the shop is a technical fit for their project.

Technical Case Studies Beat Marketing Case Studies

Most machining company case studies I review read like marketing pieces. "Customer came to us with a challenge. We delivered on time and under budget. Customer was thrilled."

Engineers don't care about this narrative. They want technical substance.

A useful case study for engineering evaluation includes:

- The actual part or part type (within confidentiality limits)

- Material and critical specifications

- Key technical challenges and how the shop solved them

- Tolerances achieved and how they were verified

- Process details that demonstrate expertise

An engineer reading a case study wants to think "these people understand problems like mine." Generic success stories don't create that recognition. Technical depth does.

The Gap Between Marketing and Engineering

Marketing teams build websites to generate leads. They focus on calls to action, value propositions, and conversion optimization. None of this is wrong, but it misses what engineers need.

Engineers aren't leads to be converted. They're technical evaluators determining fit. The information they need often gets buried under marketing messaging or omitted entirely because it seemed too detailed for a website.

This creates the gap I observe: machining company websites optimized for marketing performance that fail engineering evaluation. The contact form works perfectly, but engineers never reach it because the site didn't answer their technical questions. This same dynamic drives price competition that erodes margins when shops can't differentiate on technical capability.

Building Websites That Pass Engineering Evaluation

Pull up a machining company website and evaluate it through engineering eyes. Can they find material capabilities within two clicks? Tolerance expectations with context? Equipment information that connects to capability? Technical case studies with real substance?

If the answer is no, that website is filtering out exactly the customers the shop wants. The engineers at OEMs and contract manufacturers are researching suppliers right now. The question is whether sites give them what they need to put shops on the shortlist.

I work with precision machining companies to restructure website content for engineering evaluation. This means identifying the technical details that need prominence, organizing equipment information by capability rather than just model numbers, and developing case studies that demonstrate expertise rather than just customer satisfaction.

The shift requires understanding how engineers evaluate suppliers and what information they need at each stage of that evaluation. Sometimes shops need external perspective to identify what's missing from their technical messaging. The specifications that feel obvious internally don't always communicate what engineers need externally.

Contact Mansfield Marketing to discuss restructuring your machining company website for engineering qualification by requesting a quote or calling us at (713) 936-5557.

Written by Doug Mansfield | President, Mansfield Marketing

Connect with Doug Mansfield on LinkedIn