Serving U.S. Industrial Metal Plating Clients from Houston, Texas

Industrial Metal Plating & Coating Marketing Agency

We help electroplating shops, powder coating facilities, and finishing companies secure contracts with OEMs, fabricators, and manufacturers who specify corrosion resistance, dimensional restoration, and surface protection requirements.

Home > Industries > Industrial Metal Plating & Coating

Securing Contracts Through Technical Specification Compliance

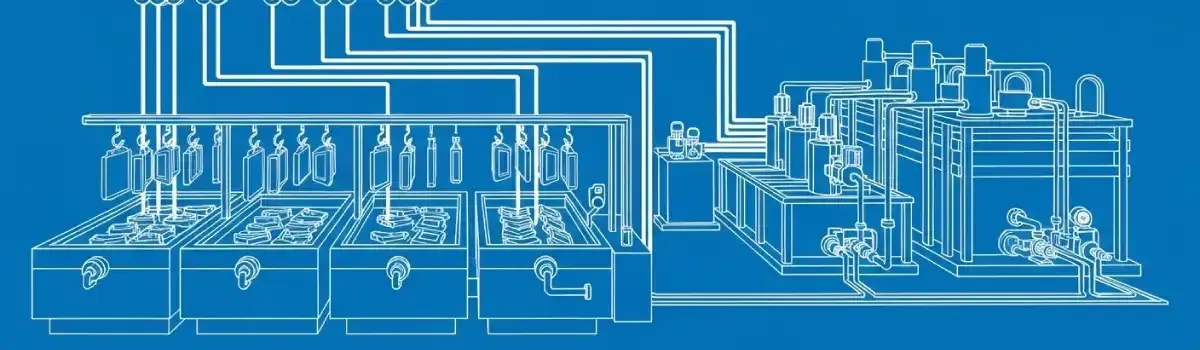

Industrial metal plating and coating companies provide essential finishing services to manufacturers across aerospace, automotive, oil and gas, and electronics sectors. These operations electroplate zinc, chrome, and nickel. They apply powder coatings, phosphate treatments, and thermal spray processes. They anodize aluminum components and passivate stainless steel parts. Each process serves specific engineering requirements for corrosion resistance, wear protection, or dimensional restoration.

The marketing challenge is procurement teams evaluating plating suppliers don't search for generic finishing services. They verify specification compliance, tank capacity limitations, and turnaround capabilities before requesting quotes. When plating company websites emphasize quality and customer service without documenting ASTM standards, ROHS compliance, or ISO 9001 certification, engineers move to suppliers who demonstrate technical qualification explicitly.

Marketing for metal finishing operations requires communicating the specifications your facility meets, the processes you control, and the industries you serve with documented quality systems.

Business Types We Serve in the Industrial Industry

"Metal Plating and Coating" covers diverse finishing processes, but the marketing needs of a high-volume barrel plating operation running automotive fasteners differ completely from a job shop providing electroless nickel for aerospace prototypes. We build specialized industrial marketing strategies for businesses that identify as:

- Electroplating Job Shops: Facilities offering rack plating or barrel plating services including zinc, cadmium, copper, nickel, chrome, tin, silver, and gold electroplating with specifications for automotive, aerospace, and defense applications.

- Hard Chrome Plating Operations: Shops specializing in industrial chrome plating for hydraulic cylinders, pump shafts, rolls, and tooling requiring wear resistance, corrosion protection, and dimensional restoration capabilities.

- Powder Coating Facilities: Operations applying electrostatic powder coatings to fabricated parts, assemblies, and equipment requiring chemical resistance, UV stability, and color-matched finishes for industrial and architectural applications.

- Anodizing and Conversion Coating Shops: Facilities providing anodizing for aluminum components, chromate conversion coatings, black oxide treatments, and phosphate coatings for corrosion protection and paint adhesion.

- Thermal Spray and Specialty Coating Companies: Operations offering HVOF, plasma spray, electric wire arc coatings, and fluoropolymer applications for demanding petrochemical, marine, and industrial reconditioning projects.

Your buyers are quality engineers, procurement managers, and manufacturing planners who evaluate finishing suppliers based on specification compliance, capacity constraints, lead time commitments, and documented quality systems before issuing purchase orders.

Strategic Approaches for Industrial Metal Finishing Operations

Procurement teams researching plating suppliers verify specification capabilities months before production orders materialize. Engineers designing components specify finishing requirements during the prototype phase. Your website needs to communicate technical qualifications when these evaluation activities occur, not after the supplier shortlist already exists.

Core Strategy Components

- Documenting process capabilities and specification compliance prominently on your website, listing the exact ASTM standards your facility meets, ROHS compliance for automotive applications, military specifications for defense work, and ISO 9001 certification for quality management systems that procurement teams verify.

- Publishing tank dimensions, part size limitations, and capacity specifications that engineering buyers need to confirm before requesting quotes, supported by technical content marketing that demonstrates finishing expertise rather than generic quality claims.

- Highlighting turnaround capabilities with realistic lead time expectations for standard jobs versus expedited service availability, addressing the production planning concerns manufacturers face when selecting finishing suppliers.

- Targeting specific industry sectors through content that addresses aerospace finishing requirements, automotive PPAP documentation needs, or oil and gas corrosion protection standards rather than generic metal finishing descriptions that fail to differentiate your facility's specialization.

Why Mansfield Is Uniquely Qualified

Operating in Houston positions Mansfield to understand the industrial finishing requirements of petrochemical equipment manufacturers, oil and gas suppliers, and aerospace component producers throughout the Gulf Coast region. There is direct experience with the technical language of electroplating specifications, thermal spray processes, and the quality documentation standards that OEM procurement teams require from finishing subcontractors. This proximity to heavy industrial manufacturing, offshore equipment fabrication, and precision component machining ensures marketing strategies align with how engineering buyers actually evaluate and select metal finishing suppliers for production contracts.

Industry Profile:

- Primary Sector: Industrial Metal Plating & Coating Services

- Primary NAICS Code: 332812

- Related Codes Served: 332813 (Electroplating, Plating, Polishing, Anodizing, and Coloring), 332710 (Machine Shops), 332999 (All Other Miscellaneous Fabricated Metal Product Manufacturing)

- Market Focus: Electroplating Services, Hard Chrome Plating, Powder Coating, Anodizing, Phosphate Coating, Thermal Spray Coatings, Electroless Nickel Plating, Passivation Services

Take the Next Step

Request a quote to discuss your current marketing challenges and determine whether Mansfield Marketing is the right fit for your industrial metal plating and coating company.

Have questions first? Contact us to discuss your specific situation.